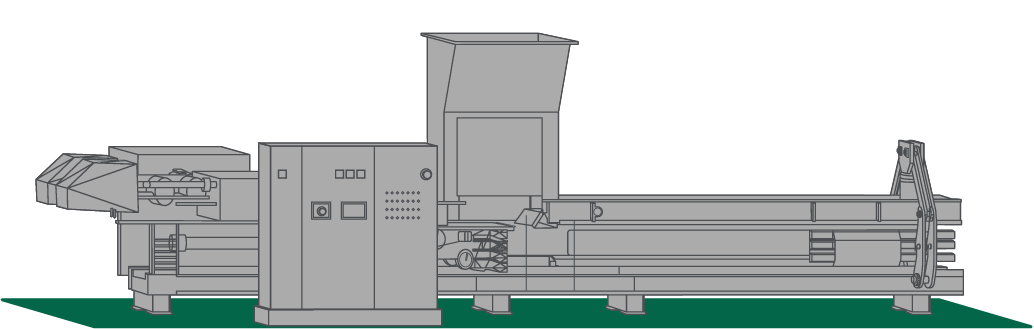

MAC 111/2

Fastest speed and highest level of performance

MAC 111/2: A RELIABLE AND HIGH-PERFORMANCE BALER IN THE CIRCULAR ECONOMY CONTEXT.

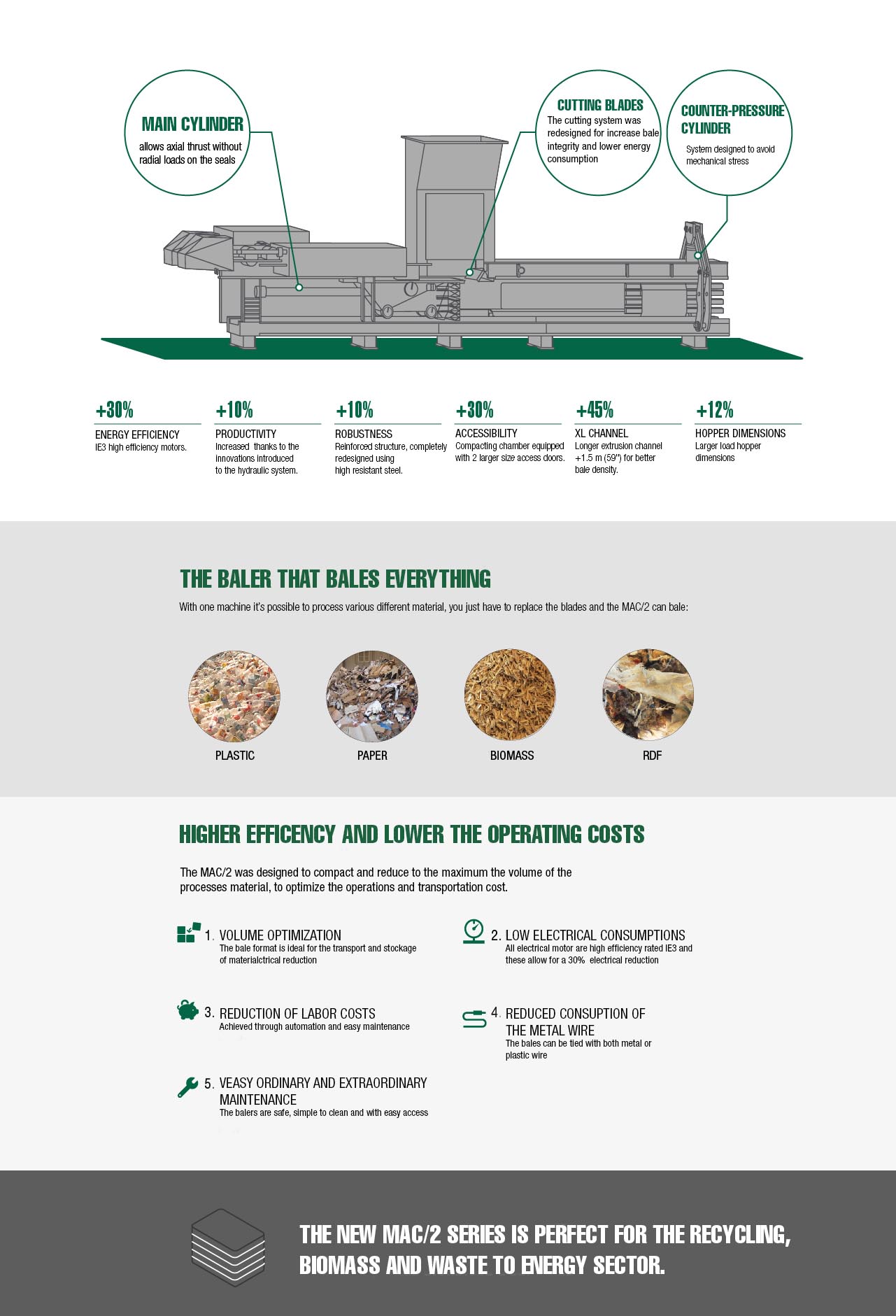

MACPRESSE EUROPA makes its contribution to circular economy by continuously evolving the technology of its range of auto-tie hydraulic balers.

As part of the guidelines aimed at improving the industrial processes efficiency, MACPRESSE has recently redesigned its MAC 111 series, replacing it with a new series of balers, The MAC /2 series, with exceptional specifics in terms of hourly output capacity and bale density of materials in relation to power consumption.

This is the context in which we have introduced the new MAC 111/2, which enhances the already well-known specifics of the previous series with new mechanical, hydraulic and electronic functional criteria and is ideal for bailing all types of materials, both in individual, medium and large plants, as well as in waste sorting plants.

In particular, the new MAC111/2 stands out for its:

- new design of the compaction chamber that guarantees hourly output up to 900 m³/h;

- new cutting blade configurations, for both the mobile or fixed type, in order to reduce the shock caused by material cutting during the most critical phase of the baling process;

- new size of the bale extrusion chamber with a more powerful setting for the hydraulic back pressure circuit to achieve a higher density for the processed materials and greater flexibility when baling mixed materials that are typical of the sorting line (MRF);

- high efficiency electric motors combined with Rexroth hydraulic piston pumps for high flow capacity at low power consumption rates;

- new electronic management of the baling phases for a total control of the baler in the working phases with an optimized interface for more precise remote diagnostics.

The MAC 111/2 baler is equipped with MACPRESSE electromechanical tying devices for wire transport, cutting and twisting, whose specifics in terms of speed, reliability and precision are well-known among operators in the sector.

For awkward materials baling, the MAC 111/2 baler integrates the protection device of the patented MACPRESSE trolley, which mechanically protects the needles slots and at the same time ensures the integrity of the steel wire. The system, combined with the mobile twisting and cutting device, guarantees the cleaning of the wire tying area with an efficiency rate close to 100%, and similar to the tying phase.

The flexibility of the MACPRESSE tying unit also allows, with minimum alteration, the replacement of the steel wire with a plastic monofilament wire, to be even made on an already operational baler.

The MAC 111/2 baler represents a further qualitative improvement of the MACPRESSE balers with the aim of providing operators in the sector with a cutting-edge machine that stands out for its ease of use, thus guaranteeing low running costs and high operational reliability.

DOWNLOAD BROCHURESMART HYDRAULIC SYSTEM

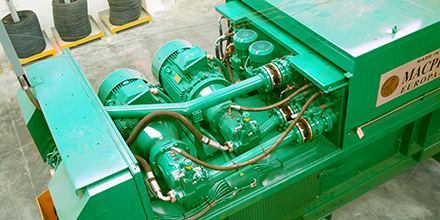

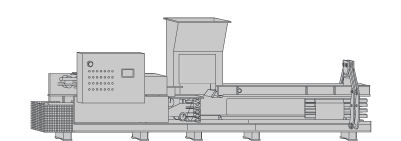

SMART HYDRAULIC SYSTEM

The hydraulic system adapts to the material that needs to be processed and the baler is equipped with pumps outside the oil tank, yet flooded, to achieve great outputs thus reducing power consumption and allowing for easier maintenance.

CONTROL PANEL

The control panel allows better management and operation of the baler. This allows to better setup production parameters – pressure and counter-pressure, bale lengths etc, check reports and statistics. At the same time, an infographics system allows you to check and troubleshoot any possible failure with a real-time diagnosis.

HIGH EFFICIENCY BLADES

HIGH-PERFORMANCE BLADES

The cutting blades are highly efficient and of a hardened material that can be changed according to the material that needs to be processed, such as OCC, Mixed Paper, and RDF/SRF.

We have also added new cutting blade configurations, both for the mobile and the fixed version, in order to limit the shock caused by cutting materials during the most critical phase of the baling process.

HARDOX STEEL LINER

HARDOX STEEL LINER

The wear resistant HARDOX steel liners are bolted into the extrusion chamber as well as the charge box chamber and can be easily replaced. This system protects the machine from abrasion and corrosion.

MAC 111/2, THE LATEST BALER OF THE MAC /2 SERIES IS IDEAL FOR BALING ALL TYPES OF MATERIALS

Europa

- PET 13 TON/H

- OCC 23.5 TON/H

- MIXED PAPER 37

- TON/H

- RDF 42 TON/H

USA

- PET 14.3 TON (US)/H

- OCC 26 TON (US)/H

- MIXED PAPER 40.7 TON (US)/H

- RDF 46.3 TON (US)/H

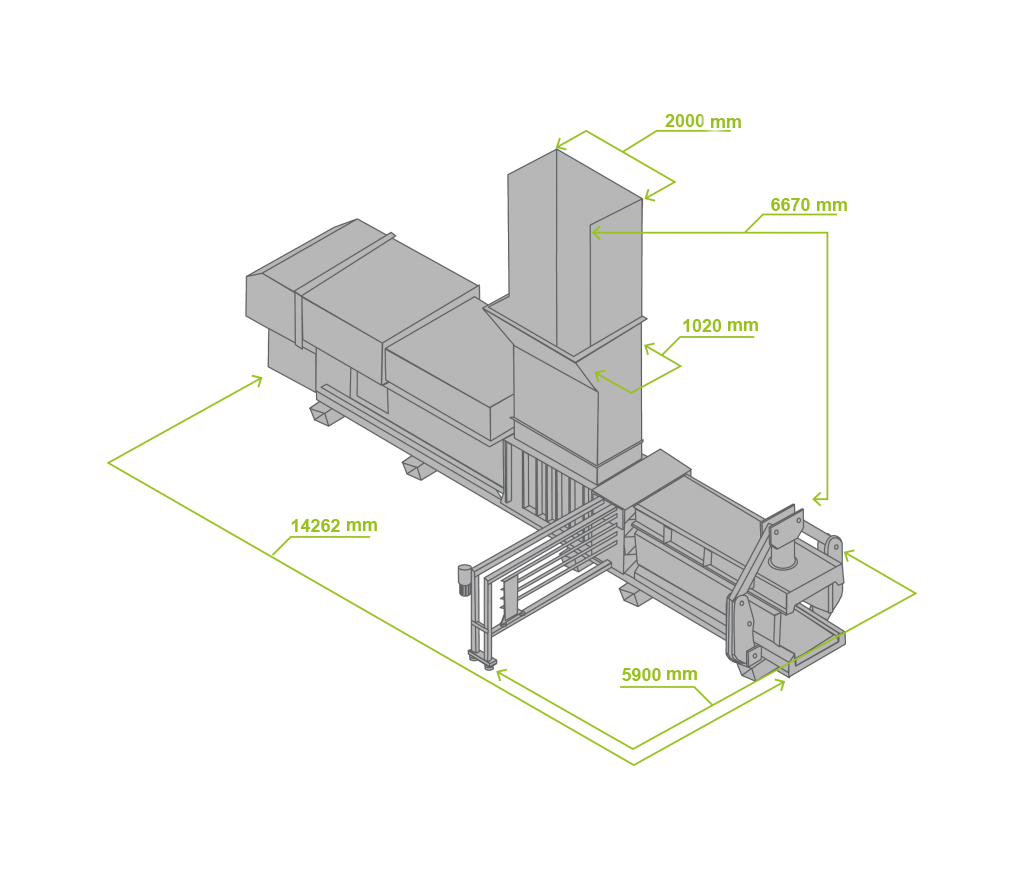

| GENERAL SPECIFICATIONS | EUROPE | USA |

|---|---|---|

| OVERALL LENGTH | 14 262 | 46’9’’ |

| MAXIMUM WIDTH | 5 900 (at tier station) | 19’4’’ |

| OVERALL HEIGHT | 4 320 (at flange hopper) | 14’2’’ |

| FEED OPENING | 2 000 x 1 020 | 79’’ x 40’’ |

| BALE DIMENSIONS | 1 100 x 1 100 | 43’’ 1/3 x 43’’ 1/3 |

| BALER WEIGHT WITHOUT FLUFFER | 44 500 Kg (without oil) | 98 106 lbs |

| BALER WEIGHT WITH FLUFFER | 49 500 Kg (without oil) | 109 130 lbs |

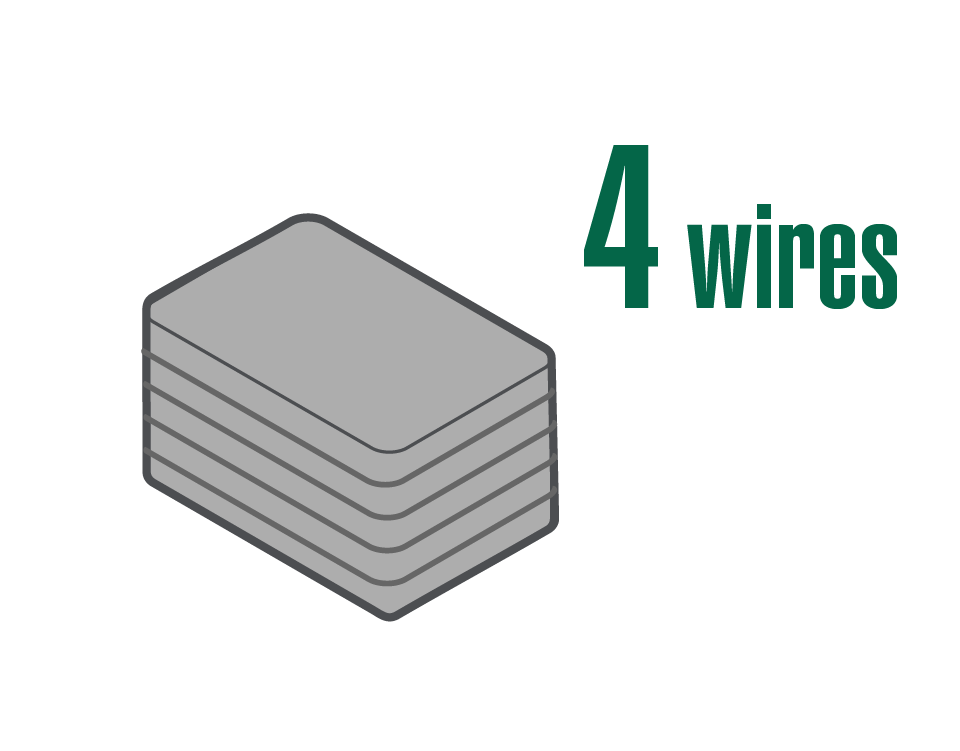

| NUMBERS OF WIRES | 5 | 5 |

Note: Performance rates, bale weights and bale densities are subject to moisture content, material pre-bale densities, feed rates nand other variables in baling.

LOADING VOLUME

VOLUMETRIC PRODUCTION

CYCLES PER MINUTE

CYCLE TIME

HORIZONTAL TYING SYSTEM

The horizontal electromechanical cutting system is designed to tie using both plastic and steel wires.

This simplifies the tying unit cleaning process and ensures greater safety for the operator. Maintenance and cleaning of the tying unit can be carried out at floor level. Wire handling operations must not be performed underneath the machine.

-

HIGH DENSITY BALES

-

WATERPROOF

-

EASY TO HANDLE

-

OPTIMAL STORAGE

-

ROAD TRANSPORT

-

RAIL TRANSPORT

-

SEA TRANSPORT