ACCESSORIES FOR MACPRESSE BALERS AND PLANTS

ACCESSORIES FOR MACPRESSE BALERS AND PLANTS: OPTIONAL ACCESSORIES FOR OPERATOR SAFETY

Our balers and our plants can be integrated with accessories providing additional protection for operators during machine maintenance and cleaning operations.

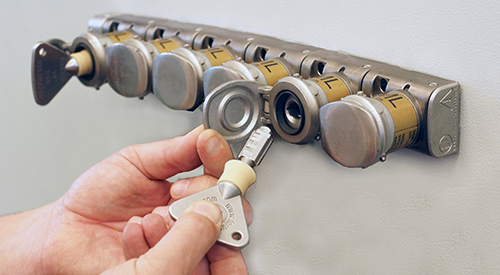

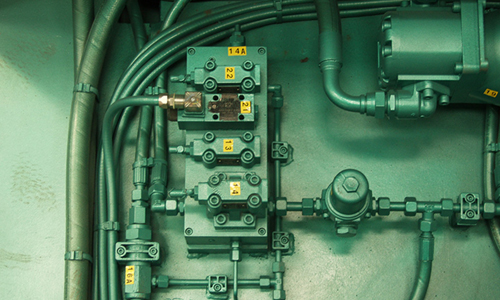

MAC SAFETY KEYS

MSK Mac safety keys system has been designed to offer enhanced safety during operations in comparison with the basic standards required by the safety regulations currently in force.

The MSK (Mac safety keys) system allows safe machine maintenance and cleaning, activating access door opening by means of Castle Lock keys. The keys are released only when the electrical control panel is switched off.

MAC SAFETY BELTS

The MACPRESSE CONVEYOR GUARDIAN safety belt system is featured with a steel cable installed along the entire ramp of the conveyor. The safety cable is connected to a safety microswitch. In case of accidental fall of the operator it is stretched by hist/her weight and disconnects the baler, thus stopping it.

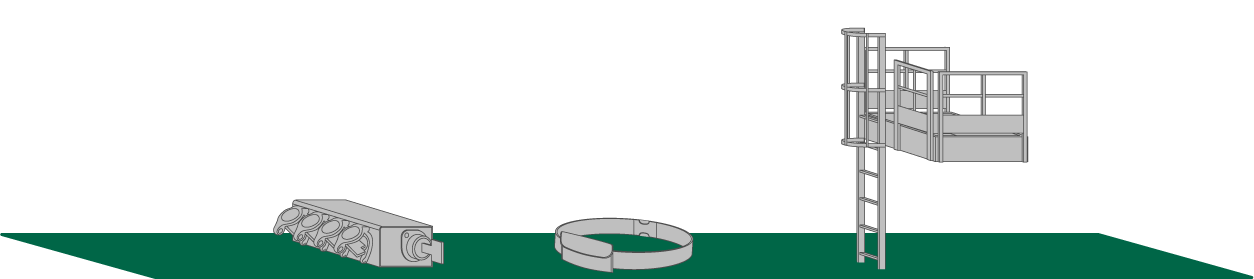

INSPECTION PLATFORM

MACPRESSE has designed a series of platforms allowing to reach some plant areas in a safe and efficient manner.

These platforms allow access to the hopper inspection door and to the conveyor belt motor.

Platforms are designed according to customer’s requirements.

ACCESSORIES FOR OPTIMAL MANAGEMENT OF MACPRESSE BALERS

Our balers and plants can be integrated with accessories that improve baler management, by monitoring anomalies, optimizing the density of the material to be baled and minimizing downtime.

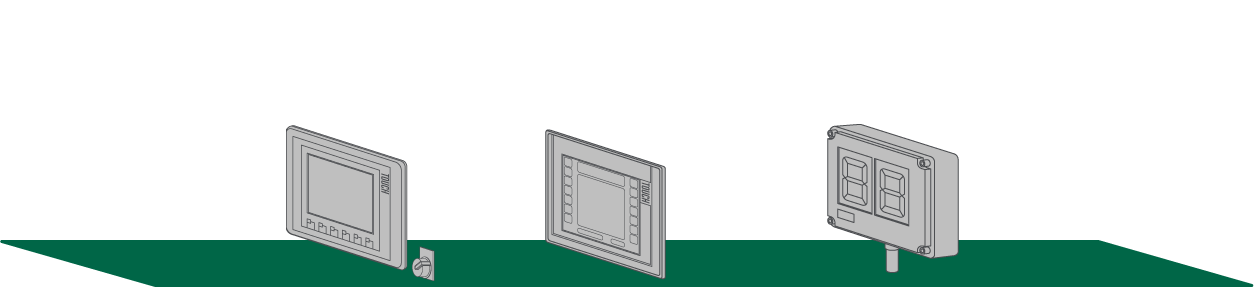

Mac Supervisor System 2

Our MSS2 system consists of a Siemens operator panel and PLC. It was designed to facilitate interaction between machine and operator. It is equipped with a diagnostic system to detect any faults, to count the number of bales and to provide remote assistance via Ethernet connection. It also allows to set the machine parameters according to the material to be processed.

Mac Supervisor System 1

The MSS1 control panel is the most advanced tool for production management for Macpresse balers. It consists of a Siemens LCD operator panel and PLC and allows maximum interaction between operator and machine, with the aim of improving production efficiency and control. The MSS1 functions include among others: real-time monitoring of faults and relative infographics, possibility of baler remote control, machine parameters management depending on the material, production reports in Excel format (hourly and total output, energy and wire consumption, statistics according to operator and work shifts).

BALE LENGTH DISPLAY

Mac balers can be equipped with a display for bale length detection, that exceeds standard dimensions: this accessory is useful in all those cases in which the operator wants to keep the length of the bales under control but is not near the machine (remember that our balers do not require constant presence of an operator, being fully automatic)

ACCESSORIES FOR OPTIMUM PRODUCTION OF BALES

Our balers and our plants can be integrated with accessories that optimize bale production and facilitate disposal on special conditions. It applies to plants for materials difficult to process such as magazines and coated paper, but also to those plants that require frequent changes of materials or that produce renewable energy, starting from waste.

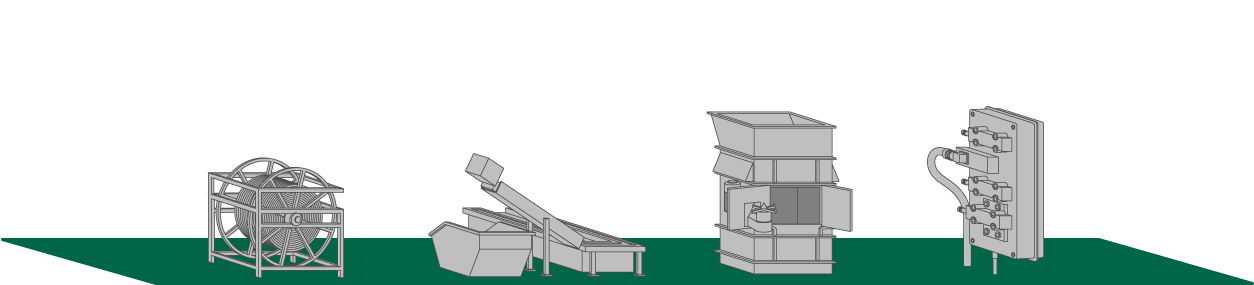

PLASTIC WIRE TYING

The MAC Poly Tie plastic tying unit has been designed especially for plants that produce refuse derived fuel (RDF) and for biomass to be sent to cement factories or waste-to-energy plants. It has been studied for plants that must burn waste because the plastic wire, unlike the iron wire, burns and does not remain as a residue in the oven. The advantage of the Poly Tie system is that it allows tying using both plastic and iron wire, simply replacing the twister hooks.

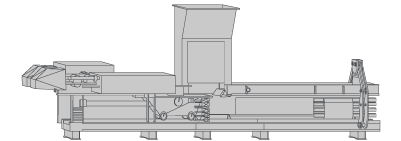

CONVEYOR FOR LEACHATE COLLECTION

This is often an indispensable accessory for balers of the L series. It consists of a conveyor with chain and scrapers installed along the entire perimeter of the baler. Its main function is to collect leachate rejected when the solid part of the waste – containing organic fraction – is separated from the liquid one. In this way, the working place is kept clean and the leachate collected may be used for purification or reuse (eg: biogas)

FLUFFER

The fluffer is a blade driven by an electric motor. It is inserted into a baler hopper and it treats magazines, newspapers and coated paper: high-density materials and/or materials extremely difficult to bale, without the need of the fluffer. The Mac fluffers have the additional advantage of being retractable, so as to speed up the loading process in the chamber of all those materials that do not require to be pre-conditioned before baling.

Mac Density Control

The MDC system (MAC Density Control) is a proportional valve that automatically controls and adjusts the working pressure of the baler, so as to obtain homogeneous bales with a maximum density depending on the material to be baled. It is suitable for recovery centres that treat a wide variety of materials, requiring different optimization parameters

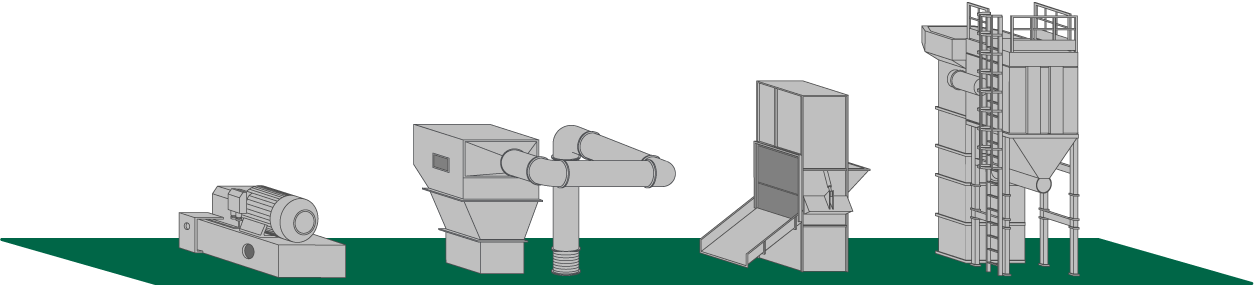

MACPRESSE HAS DESIGNED AND MANUFACTURED A SERIES OF ACCESSORIES THAT INTEGRATE AND OPTIMIZE BALER PROCESSING.

Our balers and plants can be integrated with accessories that keep the working place healthy and clean.

SOFT START MOTORS STARTER

On request, it is possible to provide the main electrical motors with a soft start starter to gradually power the motors avoiding sudden changes in voltage.

SUCTION SYSTEM FOR TRIMMINGS

Suction systems for trimmings are particularly suitable for printing plants and binderies: the pipe and suction system conveys trimmings and lightweight materials of small dimensions – which would otherwise disperse in the surrounding area – inside the hopper.

BYPASS

The Bypass system installed inside the hopper allows the materials entering into the machine to exit from an alternative way (eg. a bin) in case of machine stop (eg. for maintenance). In this way a plant downtime will not occur.

DUST SUCTION SYSTEM

The baler equipped with a shredder can be integrated with a suction system for paper dust that forms due to material shredding. This prevents machine clogging, improving air quality and reducing the risk of fire, in accordance with the ATEX directive.