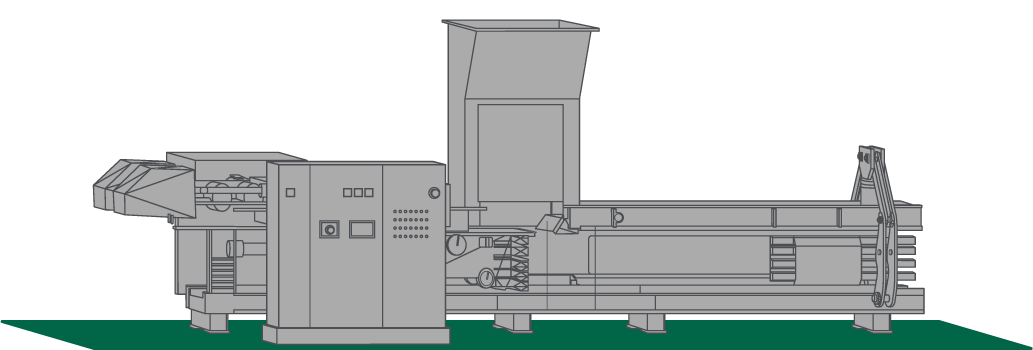

Mac 112 XL

WASTE BALER, OUR TOP OF THE RANGE

MAC 112XL: THE LARGE-SIZED BALER FOR MUNICIPAL SOLID WASTE

IT BALES MUNICIPAL SOLID WASTE, INDUSTRIAL AND COMMERCIAL WASTE, RDF (REFUSE DERIVED FUEL)

MAC 112XL is a large-sized baler for waste specially designed to treat all types of material: municipal solid waste, commercial and industrial (C&I) waste, refuse derived fuel (RDF), recyclables, biomass, unsorted municipal solid waste, even with organic material, etc.

The MAC 112XL typical users are not only transfer stations and landfills, but all those plants that must process large quantities of material in a short time, without renouncing to bale quality and density.

Download the brochure available in 6 languages

DOWNLOAD BROCHURECONTROL PANEL

The control panel allows better management and operation of the baler: production parameters can be adjusted (pressure and counterpressure, bale length, etc …), reports and statistics can be checked, and a graphics system allows a real-time diagnosis of malfunctions.

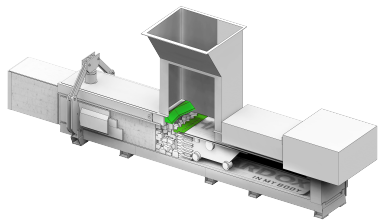

BLADES SPECIFICALLY DESIGNED FOR WASTE

The cutting system of the L series has been specifically designed to improve excess material cutting process in the hopper. Tempered blades guarantee higher wear resistance.

SMART HYDRAULIC SYSTEM

It easily adapts to the material to be treated. The pumps are outside of the oil tank for a better performance and easier maintenance.

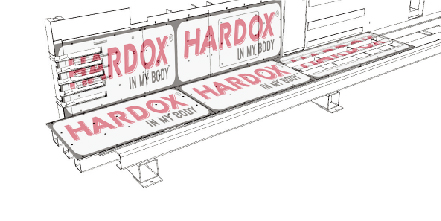

HARDOX STEEL LINER

The wear-resistant HARDOX steel liners protect the machine from abrasion and corrosion. They are bolted both into the compacting chamber and extrusion channel for easier and quicker replacement.

Europa

- RDF 52 TON/H

- C&I 60 TON/H

- MSW 68 TON/H

USA

- RDF 57.3 TON (US)/H

- C&I 66.1 TON (US)/H

- MSW 75 TON (US)/H

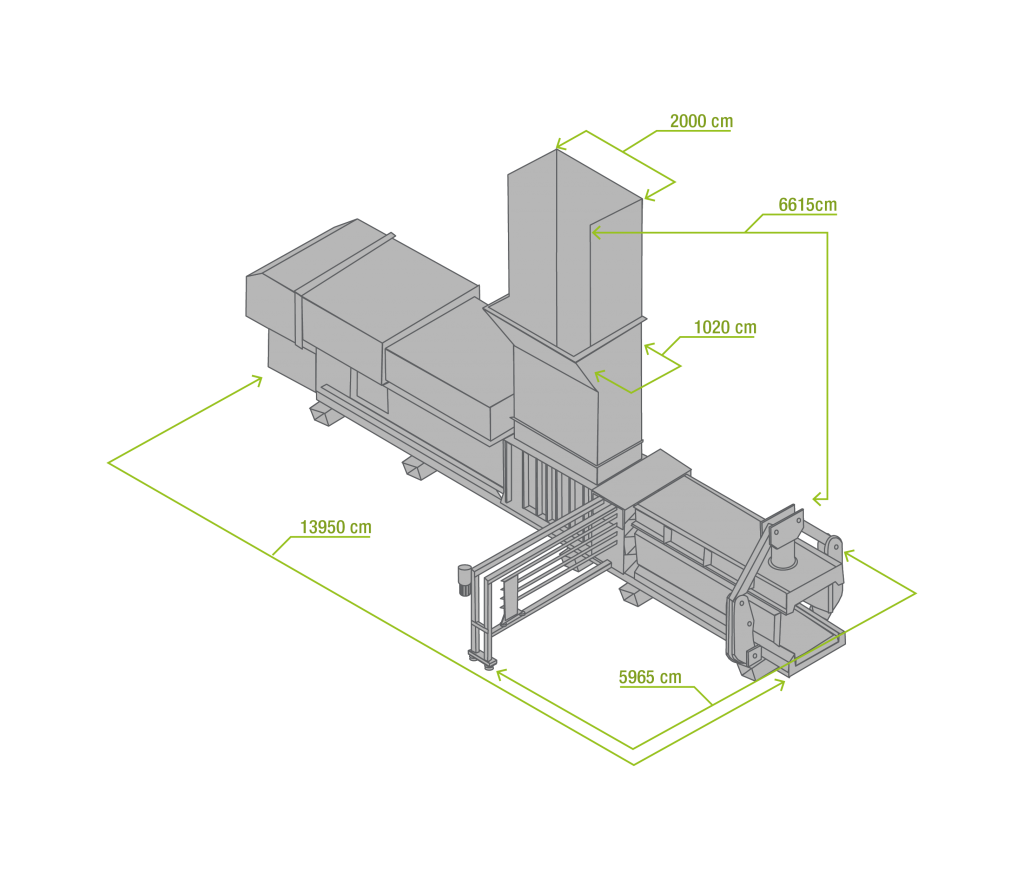

| GENERAL SPECIFICATIONS | EUROPE | USA |

|---|---|---|

| OVERALL LENGTH | 13 950 | 45’9’’ |

| MAXIMUM WIDTH | 6 125 (at tier station) | 19’7’’ |

| OVERALL HEIGHT | 4 265 (at tflange hopper) | 13'12" |

| FEED OPENING | 2 100 x 1 020 | 83’’x 40’’ |

| BALE DIMENSIONS | 1 100 x 1 100 (dimens. WxH) | 43’’1/3 x 43’’1/3 |

| BALER WEIGHT WITHOUT FLUFFER | 55 500 Kg (less oil) | 122 356 lb |

| BALER WEIGHT WITH FLUFFER | 60 600 Kg (less oil) | 133 600 lb |

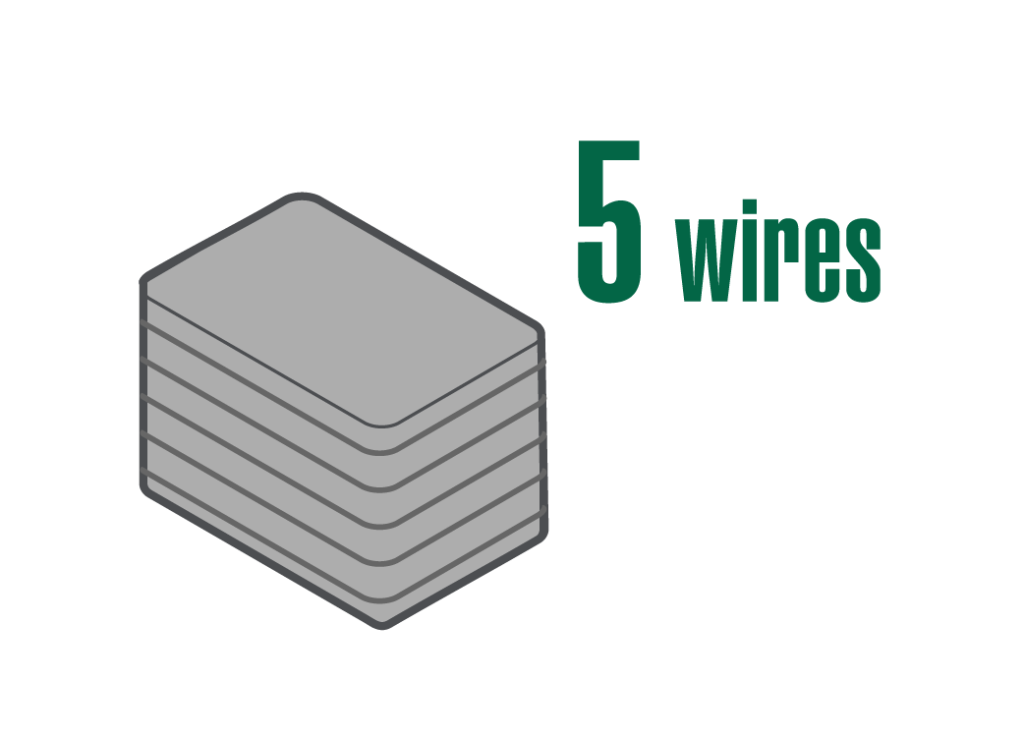

| NUMBERS OF WIRES | 5 | 5 |

Note: Performance rates, bale weights and bale densities are subject to moisture content, material pre-bale densities, feed rates nand other variables in baling.

LOADING VOLUME

VOLUMETRIC PRODUCTION

CYCLES PER MINUTE

CYCLE TIME

HORIZONTAL TYING SYSTEM

The horizontal tying system is designed for tying using both plastic and iron wires. Moreover, a series of special measures protects the system from corrosion caused by the organic fraction of waste. It may feature 5 and 4 wires.

Macpresse waste balers are also equipped with hydraulic sliding doors to protect the tying unit.

MATERIALS BALED BY mac 112

-

HIGH DENSITY BALES

-

WATERPROOF

-

EASY TO HANDLE

-

OPTIMAL STORAGE

-

ROAD TRANSPORT

-

RAIL TRANSPORT

-

SEA TRANSPORT