AN AMBITIOUS GOAL: REMOVING 40% OF LIQUID FROM MSW

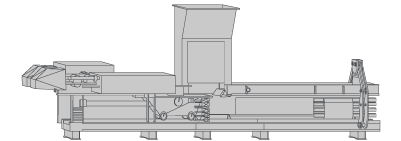

We design our balers for municipal solid waste treatment in order to recover the maximum percentage of leachate from the MSW meant for biogas plants. We installed our MAC 112 balers in a major plant in South East Asia to achieve an ambitious goal: removing 40 percent of liquid and use the leachate and the dry fraction of MSW obtained as alternative fuels for electricity production.

Dewatering serves to separate the wet fraction from waste. Then the dry fraction is sent to incinerators. The materials treated in this plant had an initial moisture content of 65% that has been reduced by up to 25%. The MAC 112 is installed on a powerful machine, equipped with a leachate collection system, i.e. a chain conveyor belt installed along the perimeter of the hydraulic baler that collects materials in tanks under the floor.

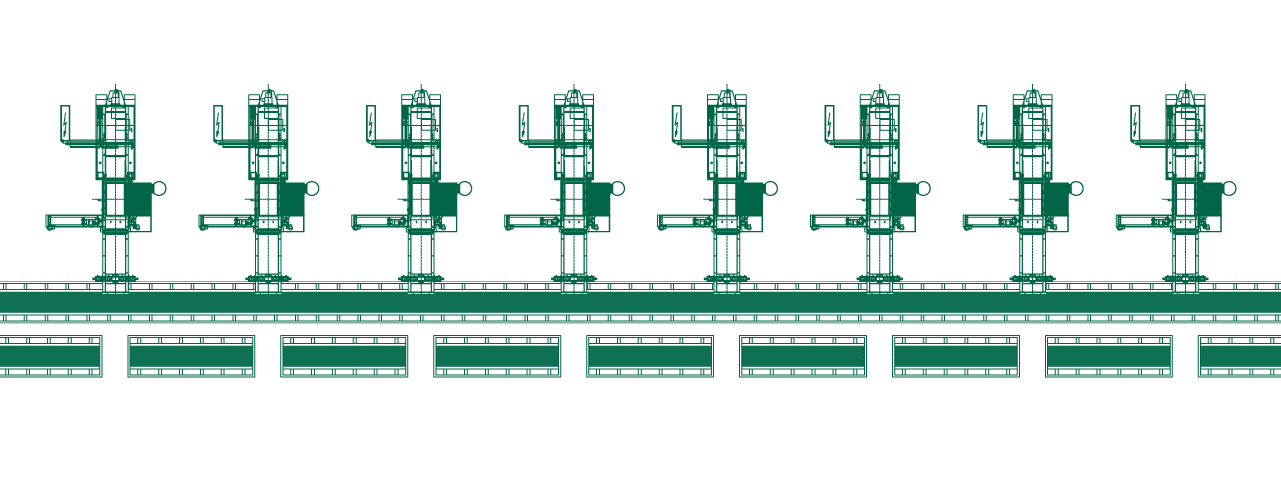

Thanks to the experience gained in the waste sector, we designed a baler able to obtain a high production of dehydrated material. This plant, equipped with a unit of eight balers, has reached an hourly production of over 600 tons/hour.

Baler for separating the organic fraction from MSW

MAC 112 is a large-sized baler for waste specifically designed to treat all types of material: municipal solid waste, commercial and industrial waste (C&I), refuse derived fuel (RDF), recyclables, biomass, unsorted municipal solid waste, even with organic material.