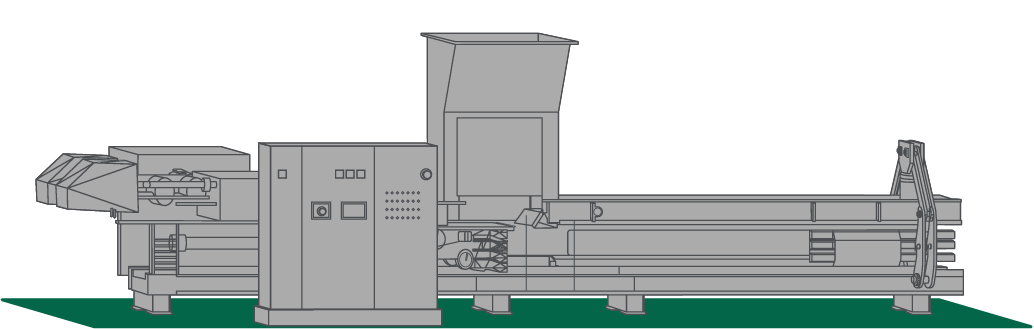

MAC 108/2

NEW STANDARDS FOR BALING PLASTICS

THE NEW MULTI-MATERIAL BALER FOR BALING PLASTIC MATERIALS

IT BALES ALL PLASTIC MATERIALS IN PARTICULAR HDPE AND PET

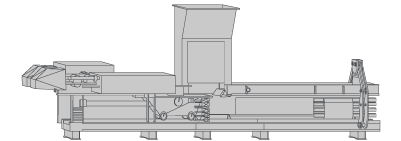

The MAC 108/2 is the second model in our new generation of balers, recommended in particular for baling plastic materials like HDPE and PET.

It is the baler for those who have medium/high production requirements and who also need to obtain very high-density bales to reach the weight limits permitted in a container.

To combine these two requests, our designers created the new machine so that it would reach a specific pressure up to more than 20 kg/cm2, with bale format of 110×75 cm to reduce the empty spaces in the cargo vehicles to a minimum.

The result is a machine can reach densities above 500 kg/m3 with non-perforated PET; by adding the smaller bale size, optimized for transport efficiency (three rows vertically), the result is the possibility to load above 24 tonnes of PET on a truck.

Thus the bales produced with this baler have very high density, ideal for arranging the maximum weight that can be loaded in a lorry and container.

A BROCHURAPAINEL DE CONTROLE

The control panel allows better management and operation of the baler: production parameters can be adjusted (pressure and counterpressure, bale length, etc …), reports and statistics can be checked, and a graphics system allows a real-time diagnosis of malfunctions.

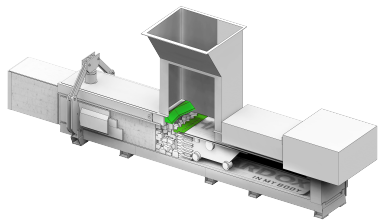

LÂMINAS DE ALTA EFICIÊNCIA

It features high efficiency and tempered cutting blades, which can be replaced according to the material to be treated: plastic, paper, biomass and refuse derived fuel (RDF).

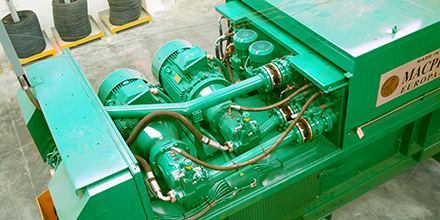

SISTEMA HIDRÁULICO INTELIGENTE

It easily adapts to the material to be treated. The pumps are outside of the oil tank for a better performance and easier maintenance.

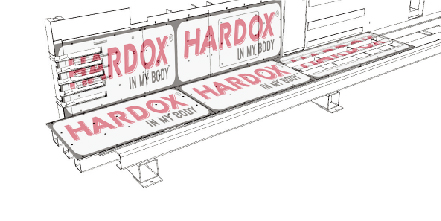

REVESTIMENTO EM AÇO HARDOX

The wear-resistant HARDOX steel liners protect the machine from abrasion and corrosion. They are bolted both into the compacting chamber and extrusion channel for easier and quicker replacement

Europa

- PET 9.5 TON/H

- CARTÃO 18 TON/H

- PAPEL MISTO 27 TON/H

- CDR 32 TON/H

USA

- PET 10.4 TON (US)/H

- CARTÃO 19.8 TON (US)/H

- PAPEL MISTO 29.7 TON (US)/H

- CDR 35.2 TON (US)/H

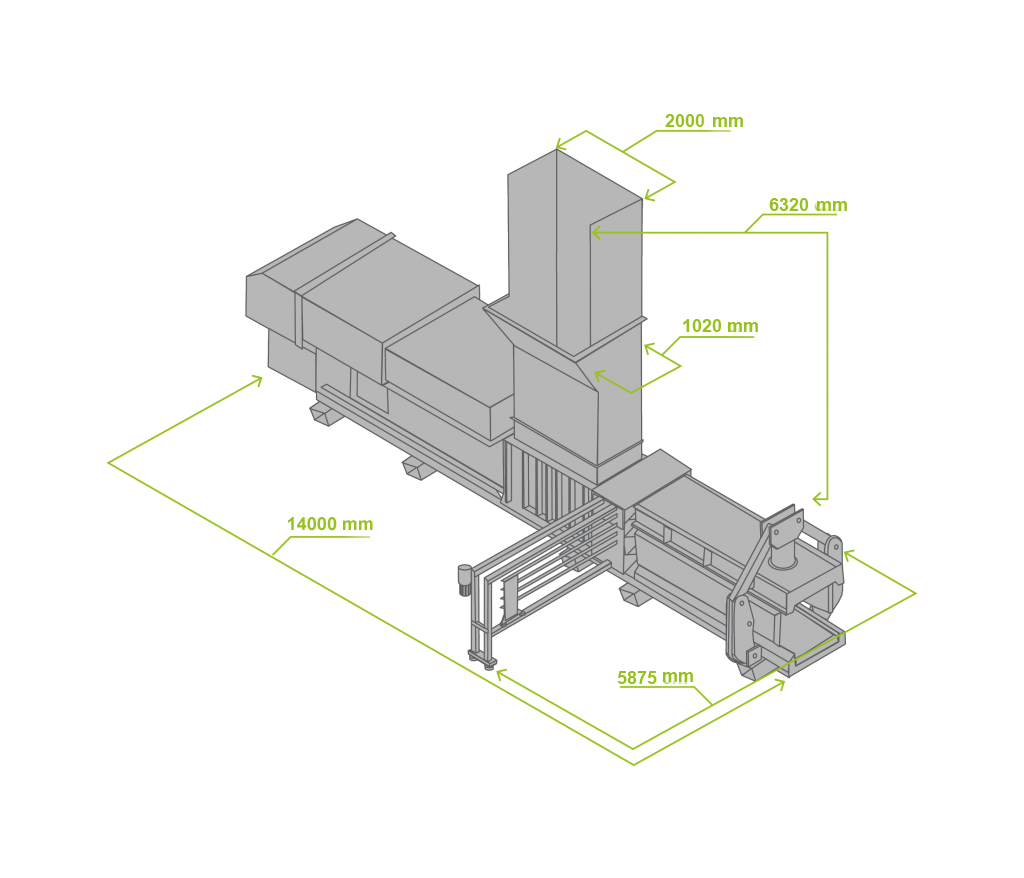

| ESPECIFICAÇÕES GERAIS | Europa (MM) | USA |

|---|---|---|

| COMPRIMENTO TOTAL | 14 000 | 45’11’’ |

| LARGURA MÁXIMA | 5 875 (na unidade de amarração) | 19’3’’ |

| ALTURA TOTAL | 3 972 (na tremonha) | 13’’ |

| TREMONHA DE CARGA | 2 000 x 1 020 | 79’’ x 40’’ |

| DIMENSÕES DOS FARDOS | 1 100 x 750 (dimens. LxH) | 43’’ 1/3 x 29’’1/2 |

| PESO DA PRENSA ENFARDADORA SEM DESFOLHADORA | 40 000 Kg (menos óleo) | 88 184 lbs |

| PESO DA PRENSA ENFARDADORA COM DESFOLHADORA | 45 000 Kg (menos óleo) | 99 208 lbs |

| NÚMERO DE ARAMES | 4 | 4 |

Taxas de desempenho, peso e densidade dos fardos dependem da umidade, denisidade pre-enfardamento, taxa de alimentaçao da máquina, velocidade de entrada e outras variaveis que podem influir no processo de enfardamento.

VOLUME DE CARGA

PRODUÇÃO VOLUMÉTRICA

CICLOS POR MINUTO

TEMPO DE CICLO

Horizontal tying system

ELECTROMECHANICAL HORIZONTAL TYING SYSTEM DESIGNED FOR TYING BOTH PLASTIC AND STEEL WIRES

This system simplifies the cleaning process for the tying machine, guaranteeing greater safety for the operator. The maintenance and cleaning of the tying machine are carried out at floor level, operations on the steel wire are not required beneath the machine.

MATERIALS BALED BY mac 108/2

-

FARDOS DE ELEVADA DENSIDADE

-

IMPERMEÁVEL

-

FÁCIL MANUSEAMENTO

-

ARMAZENAMENTO ÓTIMO

-

TRANSPORTE RODOVIÁRIO

-

TRANSPORTE FERROVIÁRIO

-

TRANSPORTE MARÍTIMO