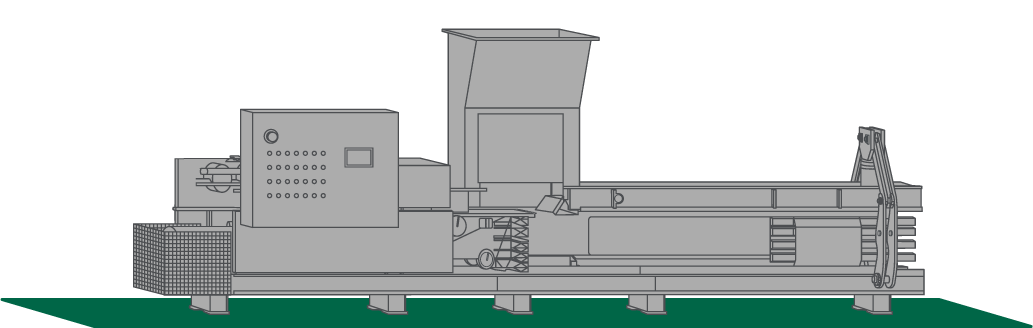

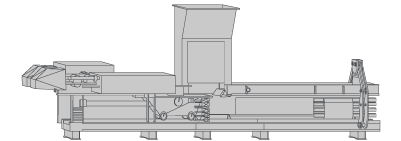

Mac 106/2

NEW BALER MAC106/2 THE LATEST MODEL OF THE /2 SERIES

MAC 106/2: MIDSIZE FOR RECYCLABLES AND RDF

BALES MEDIUM QUANTITIES OF MATERIALS COMING FROM SEPARATE COLLECTION

The MAC 106/2 is the latest model of the /2 series. It processes all kinds of materials coming from the separate collection.

MAC 106/2 baler has been designed for processing medium quantities of materials coming from the separate collection: plastic, PET, mixed paper, OCC and refuse derived fuel (RDF).

The result is a higher density of the bales combined with greater production, without requiring excessive effort from the machine.

The bale size obtained is ideal to optimize storage and transport using most common trucks, containers, and railroad cars.

Download the brochure available in English languages

DESCARGAR FOLLETOPANEL DE CONTROL

The control panel allows better management and operation of the baler: production parameters can be adjusted (pressure and counterpressure, bale length, etc …), reports and statistics can be checked, and a graphics system allows a real-time diagnosis of malfunctions.

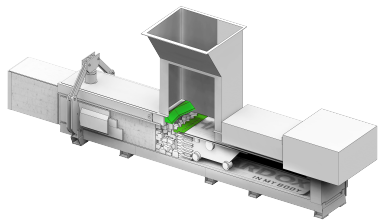

CUCHILLAS DE ALTA EFICIENCIA

It features high efficiency and tempered cutting blades, which can be replaced according to the material to be treated: plastic, PET, mixed paper, OCC and refuse derived fuel (RDF).

SISTEMA HIDRÁULICO INTELIGENTE

Smart system adaptable to material Pumps positioned outside of oil tank for a better performance and easier maintenance.

REVESTIMIENTO DE ACERO HARDOX

The wear-resistant HARDOX steel liners are bolted into the extrusion channel and into the compacting chamber and can be easily replaced, protecting the machine from abrasion and corrosion.

Europa

- PET 6 TON/H

- OCC 12 TON/H

- MIX PAPER 20 TON/H

- RDF 24 TON/H

USA

- PET 6.6 TON (US)/H

- OCC 13.2 TON (US)/H

- MIX PAPER 22 TON (US)/H

- RDF 26.4 TON (US)/H

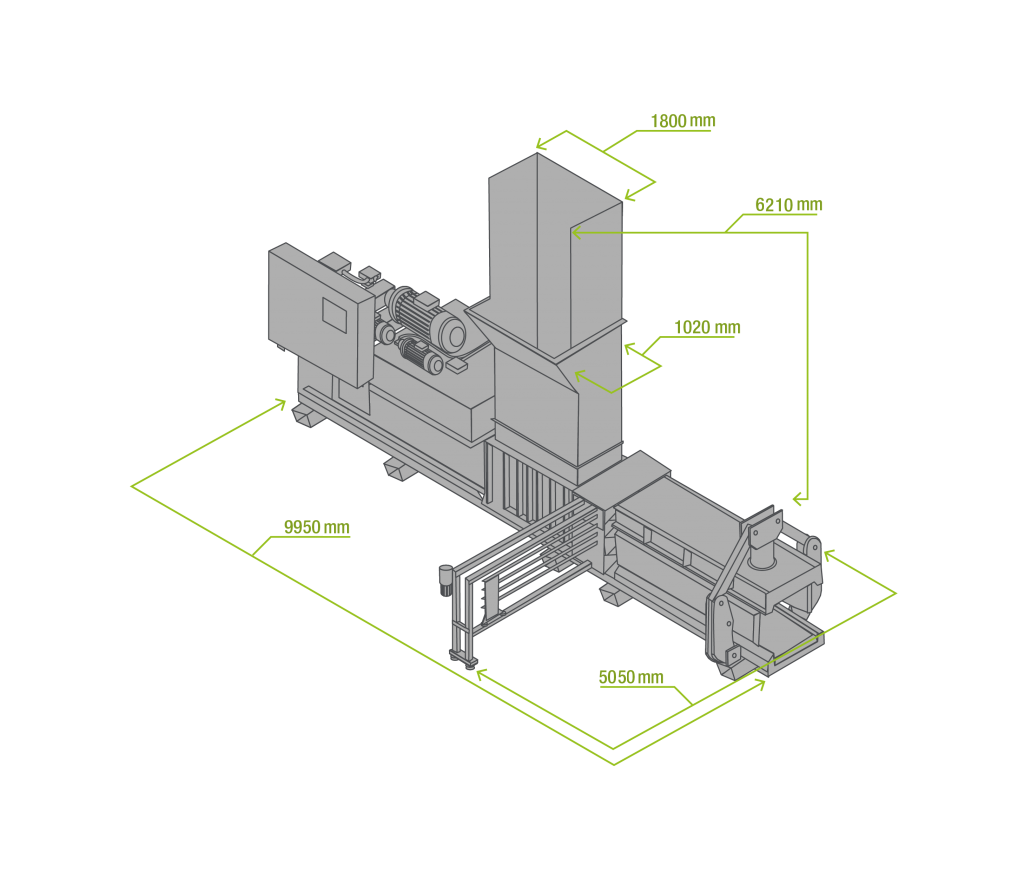

| ESPECIFICACIONES GENERALES | Europa (MM) | USA |

|---|---|---|

| LONGITUD TOTAL | 9 950 | 32’8’’ |

| ANCHURA MÁXIMA | 5 050 (na unidade de amarração) | 16’7’’ |

| ALTURA TOTAL | 3 860 (na tremonha) | 12’7’’ |

| TOLVA DE CARGA | 1 800 x 1 020 | 71’’ X 40’’ |

| TAMAÑO DE LAS BALAS | 1 100 x 750 (dimens. LxH) | 43’’1/3 x 29’’1/2 |

| PESO PRENSA SIN PREACONDICIONADOR | 21 000 KG (menos óleo) | 46 297 lb |

| PESO PRENSA CON PREACONDICIONADOR | 25 500 KG (menos óleo) | 56 217 lb |

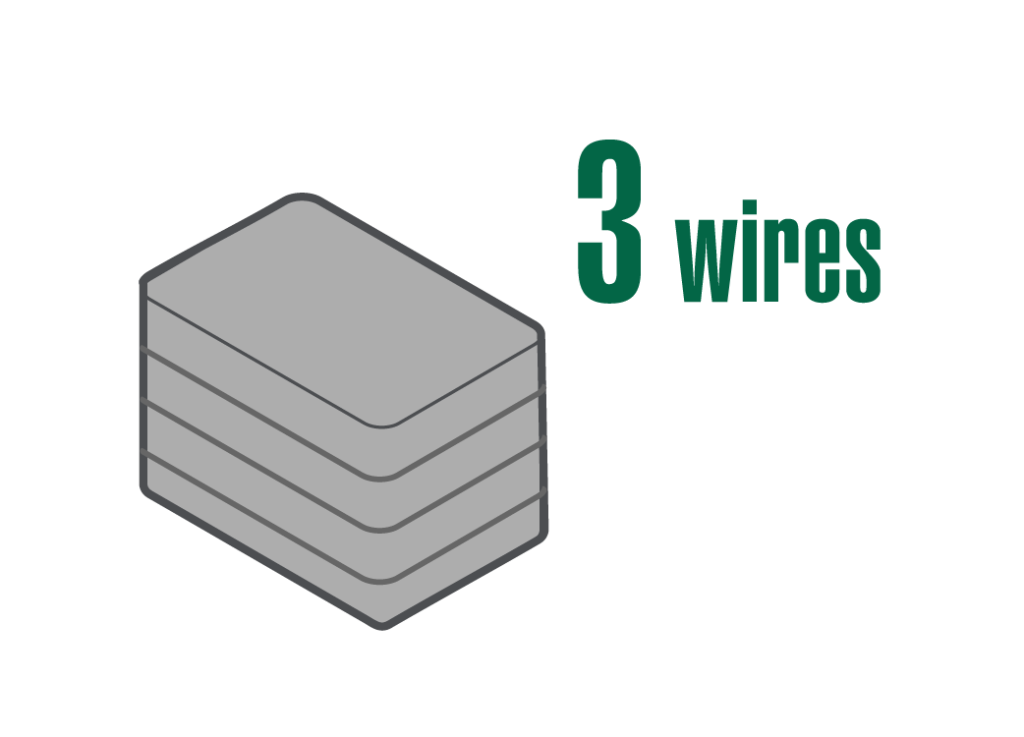

| NÚMERO DE ATADOS | 4 | 4 |

Las tasas de retorno, el peso y la densidad de las balas son dependientes de la humedad y la densidad del material de entrada, velocidad de alimentación y otras variables que pueden afectar el proceso de embalaje

VOLUMEN DE CARGA

PRODUCCIÓN VOLUMÉTRICA

CICLOS POR MINUTO

TIEMPO DE CICLO

HORIZONTAL TYING SYSTEM

ELECTRO-MECHANICAL HORIZONTAL TYING SYSTEM DESIGNED FOR TYING BOTH PLASTIC AND STEEL WIRES

This system simplifies the cleaning process for the tying unit, providing increased safety for the operator. The maintenance and cleaning of the tying unit is done at floor level; replacement of baling wire is at floor level, no pit needed.

MATERIALS BALED BY mac 106/2

-

BALAS DE ALTA DENSIDAD

-

IMPERMEABLE

-

FÁCILES DE MANEJAR

-

ÓPTIMO ALMACENAJE

-

TRANSPORTE POR CARRETERA

-

TRANSPORTE FERROVIARIO

-

TRANSPORTE MARÍTIMO