Mac 110/2

EXPERIENCE BECOMES INNOVATION

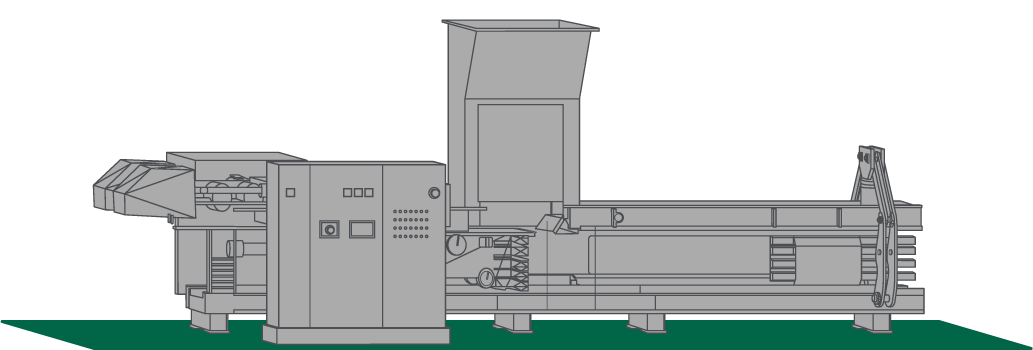

MAC 110/2: THE MULTI-MATERIAL BALER FOR RECYCLABLES

PET, OCC, MIXED PAPER, RDF (REFUSE DERIVED FUEL)

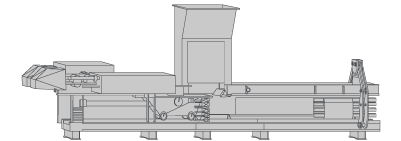

MAC 110/2 is a versatile baler: it bales different materials, such as plastic, paper, biomass and refuse derived fuel (RDF). Compared to the previous series of the MAC range it is even more performing: more efficient, sturdier, easier to clean. It can quickly handle large workloads and, at the same time, it ensures greater bale density.

Find out our customers’ opinion about the MAC 110/2 or download the brochure available in 6 languages

DOWNLOAD BROCHURECONTROL PANEL

The control panel allows better management and operation of the baler: production parameters can be adjusted (pressure and counterpressure, bale length, etc …), reports and statistics can be checked, and a graphics system allows a real-time diagnosis of malfunctions.

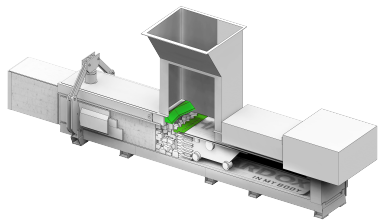

HIGH EFFICIENCY BLADES

It features high efficiency and tempered cutting blades, which can be replaced according to the material to be treated: plastic, paper, biomass and refuse derived fuel (RDF).

SMART HYDRAULIC SYSTEM

It easily adapts to the material to be treated. The pumps are outside of the oil tank for a better performance and easier maintenance.

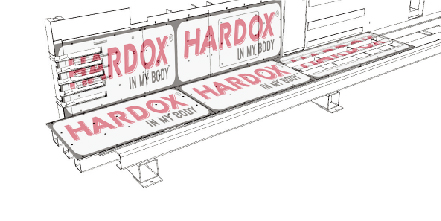

HARDOX STEEL LINER

The wear-resistant HARDOX steel liners protect the machine from abrasion and corrosion. They are bolted both into the compacting chamber and extrusion channel for easier and quicker replacement

Macpresses 110/2 compared to previous model

Europa

- PET 12 TON/H

- OCC 22 TON/H

- MIXED PAPER 35 TON/H

- RDF 40 TON/H

USA

- PET 13.3 TON (US)/H

- OCC 24 TON (US)/H

- MIXED PAPER 38.5 TON (US)/H

- RDF 44.8 TON (US)/H

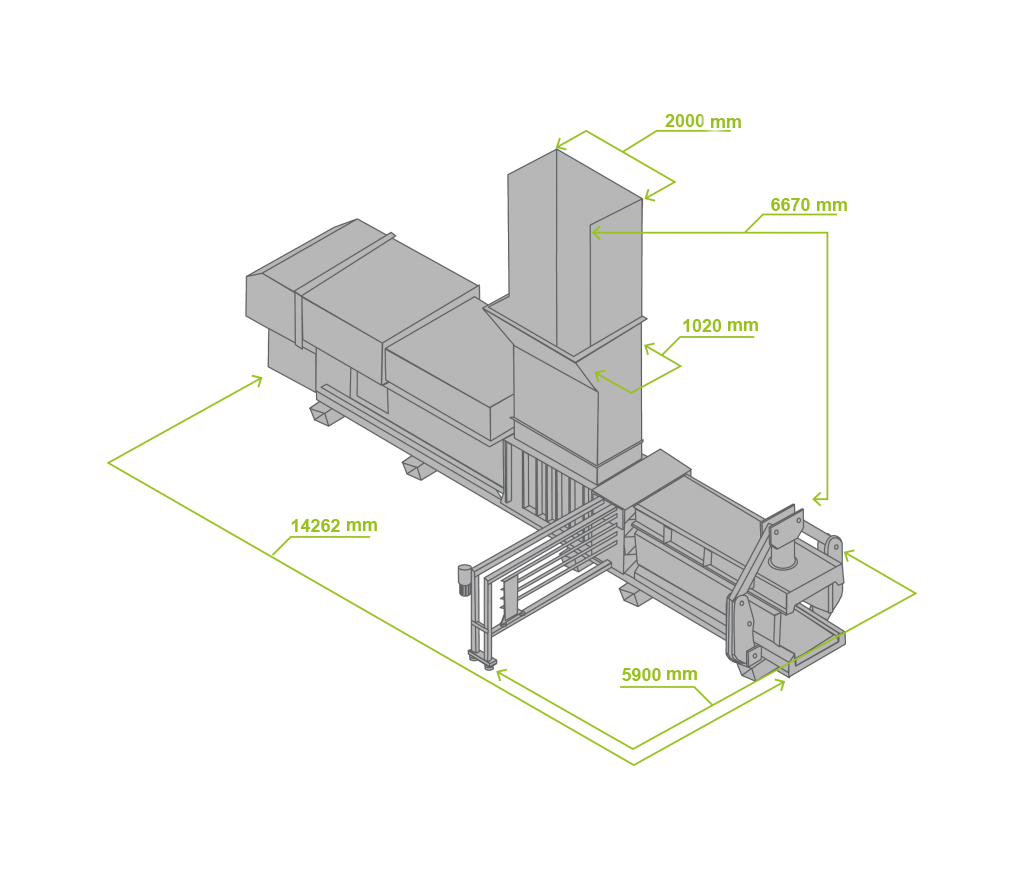

| GENERAL SPECIFICATIONS | EUROPE | USA |

|---|---|---|

| OVERALL LENGTH | 14 262 | 46'9" |

| MAXIMUM WIDTH | 5 900 (at tier station) | 19'4" |

| OVERALL HEIGHT | 4 320 (at flange hopper) | 14'2" |

| FEED OPENING | 2 000 x 1 020 | 79" x 40" |

| BALE DIMENSIONS | 1 100 x 1 100 | 43"1/3 x 43"1/3 |

| BALER WEIGHT WITHOUT FLUFFER | 43 000 Kg (less oil) | 94 800 lbs |

| BALER WEIGHT WITH FLUFFER | 48 000 Kg (less oil) | 105 820 lbs |

| NUMBERS OF WIRES | 5 | 5 |

Note: Performance rates, bale weights and bale densities are subject to moisture content, material pre-bale densities, feed rates nand other variables in baling.

LOADING VOLUME

VOLUMETRIC PRODUCTION

CYCLES PER MINUTE

CYCLE TIME

Horizontal tying system

The horizontal tying system is designed to tie both plastic and iron wires: it simplifies the tying unit cleaning process and ensures greater operator safety. It may feature 4, 5 and 5+3 wires.

MATERIALS BALED BY mac 110/2

-

HIGH DENSITY BALES

-

WATERPROOF

-

EASY TO HANDLE

-

OPTIMAL STORAGE

-

ROAD TRANSPORT

-

RAIL TRANSPORT

-

SEA TRANSPORT