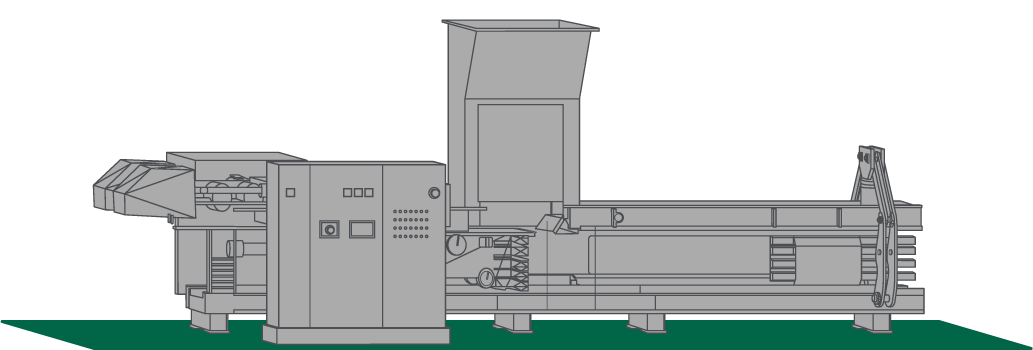

Mac 110/1

LARGE-SIZED BALER FOR RECOVERY OF SECONDARY RAW MATERIALS

MAC 110/1: THE BALER FOR RECOVERY OF SECONDARY RAW MATERIALS PROCESSING LARGE QUANTITIES OF PRODUCT

IT BALES ALL MATERIALS COMING FROM SEPARATE COLLECTION, SUCH AS PET, OCC AND MIXED PAPER

OCC, PET, mixed paper and other materials meant to be recycled. The bale size obtained with the MAC 110/1 baler is perfect for storage and transport using the most common methods, such as trucks, containers and railroad cars.

CONTROL PANEL

The control panel allows better management and operation of the baler: production parameters can be adjusted (pressure and counterpressure, bale length, etc …), reports and statistics can be checked, and a graphics system allows a real-time diagnosis of malfunctions.

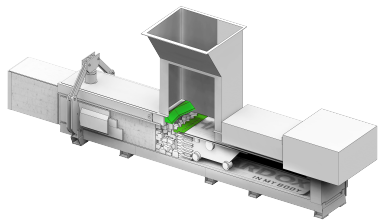

HIGH EFFICIENCY BLADES

The cutting system is a high efficiency system and the blades of the MAC 110/1 baler are tempered and wear-resistant to optimize the excess material cutting process in the hopper.

SMART HYDRAULIC SYSTEM

The hydraulic system adapts to the material to be treated and the baler is equipped with pumps outside of the oil tank for better performance and easier maintenance.

Installing variable flow pumps offers better performance with reduced energy consumption. High efficiency IE3 electric motors with an energy saving of 30% compared to traditional motors.

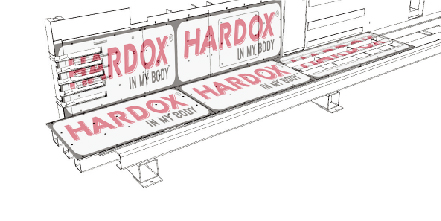

HARDOX STEEL LINER

The MAC 110/1 baler is protected with wear-resistant HARDOX steel liners which are bolted into the extrusion channel and into the compacting box and can be easily replaced.

Europa

- PET 10 TON/H

- CARDBOARD 18 TON/H

- MIX PAPER 30 TON/H

- RDF/SRF 35 TON/H

USA

- PET 11 TON(US)/H

- CARDBOARD 20 TON(US)/H

- MIX PAPER 33.1 TON(US)/H

- RDF/SRF 37.5 TON/H

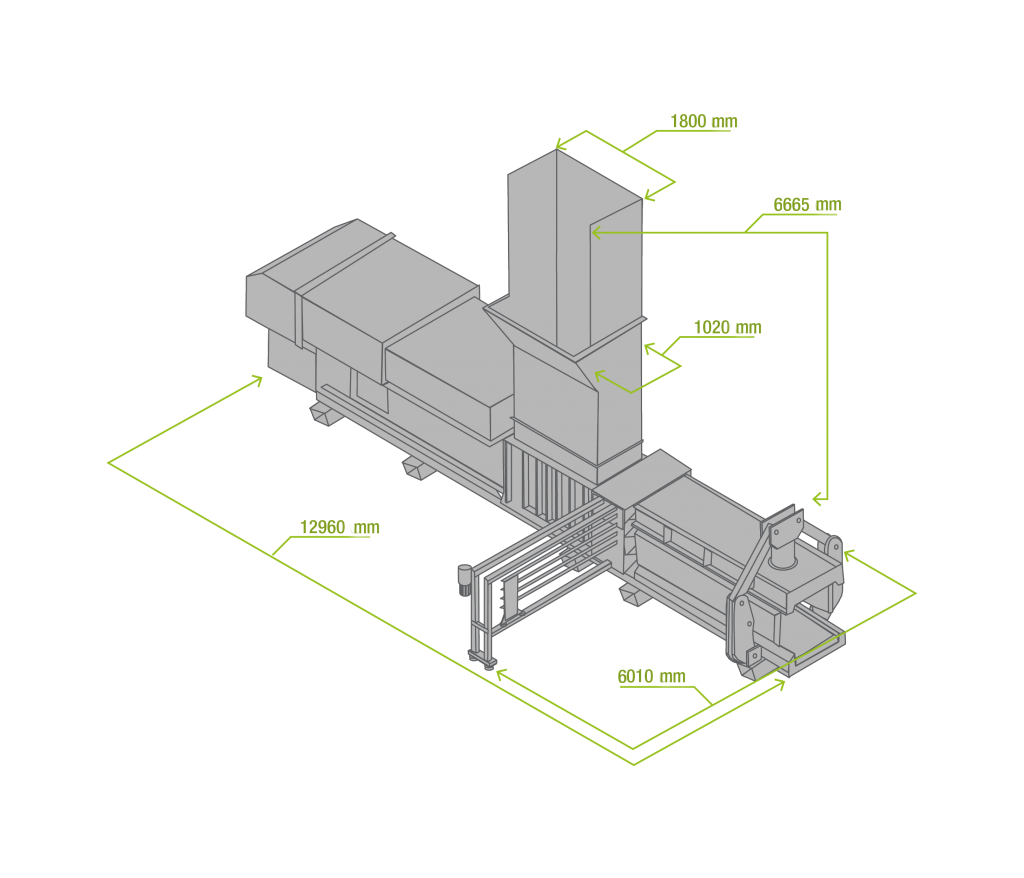

| GENERAL SPECIFICATIONS | EUROPE | USA |

|---|---|---|

| OVERALL LENGTH | 12 960 | 42'6" |

| MAXIMUM WIDTH | 6 010 (at tier station) | 19'9" |

| OVERALL HEIGHT | 4 315 (at flange hopper) | 14'2" |

| FEED OPENING | 1 800 x 1 020 | 71" x 40" |

| BALE DIMENSIONS | 1 100 x 1 100 (dimens. WxH) | 43"1/3 x 43"1/3 |

| BALER WEIGHT WITHOUT FLUFFER | 40 900 Kg (less oil) | 90 169 lb |

| BALER WEIGHT WITH FLUFFER | 45 900 Kg (less oil) | 109 128 lb |

| NUMBERS OF WIRES | 5 | 5 |

Note: Performance rates, bale weights and bale densities are subject to moisture content, material pre-bale densities, feed rates nand other variables in baling.

LOADING VOLUME

VOLUMETRIC PRODUCTION

CYCLES PER MINUTE

CYCLE TIME

Horizontal tying system

MAC 110/1 bales large quantities of materials coming from separate collection and its electromechanical horizontal tying system can feature a 5+3, 5 or 4 wires.

MATERIALS BALED BY mac 110/1

-

HIGH DENSITY BALES

-

WATERPROOF

-

EASY TO HANDLE

-

OPTIMAL STORAGE

-

ROAD TRANSPORT

-

RAIL TRANSPORT

-

SEA TRANSPORT